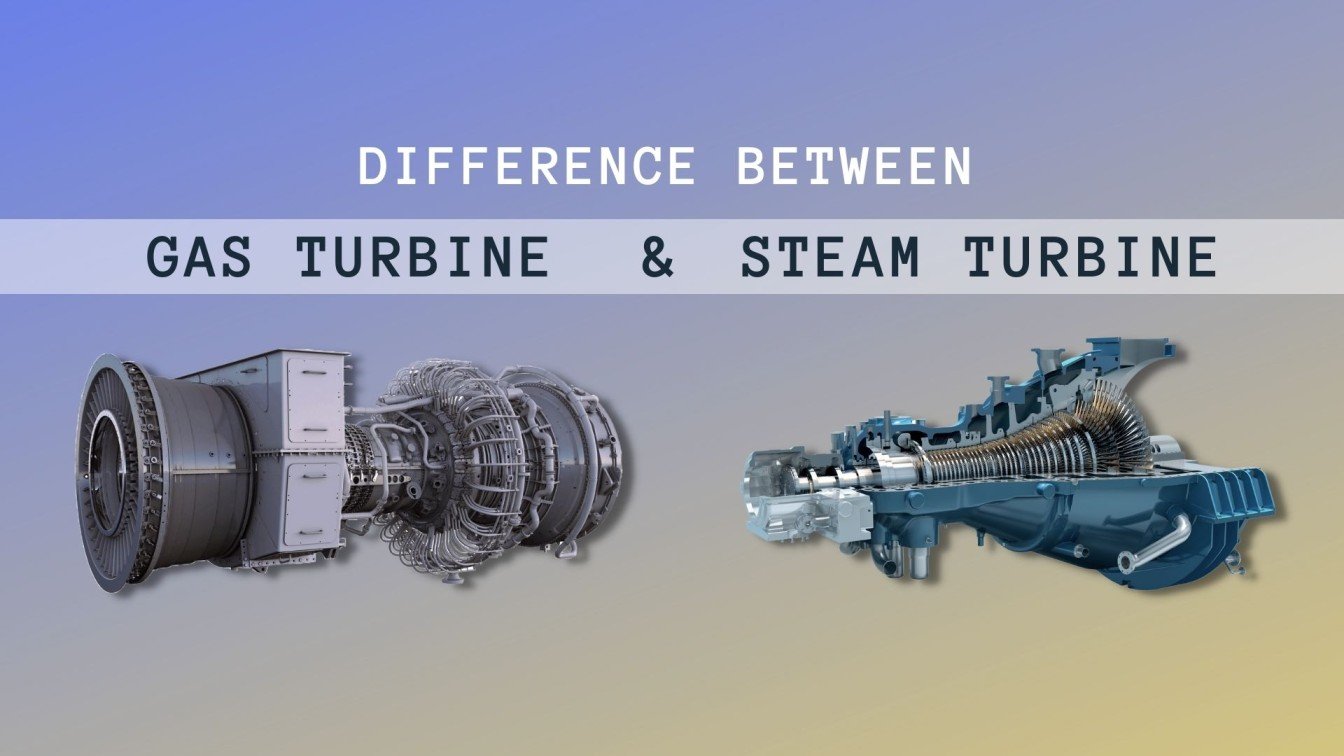

What Is The Difference Between Gas And Steam Turbine?

Electricity is generated in power plants in different ways. Steam and gas are two typical materials used to generate electricity, and each requires different equipment and operating states to achieve maximum performance. Here’s a quick overview of the steam and gas turbines, including the significant differences.

What is a Gas Turbine?

A gas turbine engine is an internal combustion engine that uses gases such as air as the operating fluid. The Brayton cycle is an excellent model for the thermodynamic side of gas turbine operation. As a result, the blades are cooled by air passing through microscopic gaps and forming a “protective film” between the exhaust gases and the blades. The blade material would swiftly wear out if it wasn’t kept cool.

- Combustion of fossil fuels with compressed air produces highly hot exhaust gases. These gases come into contact with turbine blades, spinning them to generate power. The Brayton or Joule Cycle is a method of generating energy from compressed air and fuel. The noise generated by air entering a gas turbine for combustion is often significant, which facility managers can reduce by installing inlet silencers. The exhaust makes noise on its way out, which is addressed by specialized exhaust silencers.

- These gases are substantially hotter than those used in steam turbines, reaching temperatures of up to 1500 °C. One advantage over steam turbines is that, because water isn’t used in the process, there’s no possibility of internal freezing, bringing your business to a halt. Gas turbines, on the other hand, require fossil fuels, and the combustion process produces pollutants such as nitrogen oxide.

- The compressor, combustion chamber, and turbine, which are assembled along a rotating shaft to accomplish separate functions of an internal combustion engine, are the fundamental components of a gas turbine engine, unlike a steam turbine. The gas input from the inlet is compressed first by an axial compressor, which works in the opposite direction of a simple turbine. The compressed gas is then routed via a diffuser (a diverging nozzle) stage, which reduces the velocity of the gas while increasing the temperature and pressure.

- The gas is then introduced into the combustion chamber, where it is mixed with fuel and ignited. As a result, the temperature and pressure of the gas rise to incredible heights as a result of combustion. The gas then flows through the turbine portion, which causes the shaft to rotate as it goes through. A large gas turbine can achieve shaft rotation rates of up to 10,000 RPM, whereas smaller turbines can produce up to five times that. Gas turbines can generate torque (through the rotating shaft), thrust (by high-speed gas exhaust), or a combination of the two. The mechanical work produced by the shaft in the first scenario, as in the steam turbine, is simply a transition of the enthalpy (pressure) of the high temperature and pressure gas.

- An internal mechanism uses a portion of the shaft work to drive the compressor. This type of gas turbine is mostly utilized to generate electricity and as a power source for vehicles such as tanks and automobiles. Gas turbines can generate torque (through the rotating shaft), thrust (by high-speed gas exhaust), or a combination of the two.

- The mechanical work produced by the shaft in the first scenario, as in the steam turbine, is simply a transition of the enthalpy (pressure) of the high temperature and pressure gas.

- The thrust is provided by the exhaust gas in the second example, which is directed via a converging nozzle to enhance velocity. This type of gas turbine is also known as a jet or turbojet engine, and it is used to power military fighter aircraft. The turbofan is a more advanced version of the above, while turboprop engines, which use shaft work to drive a propeller, use a combination of thrust and work generation.

What is a Steam Turbine?

Steam turbines spin as a result of hot water vapor currents. They are part of a closed water cycle in which water condenses, is heated, and finally evaporates. Steam turbines, on the other hand, do not come into contact with the fuel used and operate at temperatures ranging from 500 to 650 degrees Celsius. Several steam turbines are frequently positioned in a row so that they can optimally convert the respective steam pressure into rotary movement depending on whether they are set for high, medium, or low pressure.

- The main distinction between steam and gas turbines is that steam turbines use expanding steam to generate electricity. Natural gas, for example, can be used to heat condensed water in a boiler, although renewable thermal energy can also be used. This heated water condenses into steam, which spins turbine blades to generate electricity. The internal temperature is only 500 to 650 degrees Celsius, which is less than half that of gas turbine reactions.

- Steam turbines, unlike gas turbines, do not have an air compressor or a combustion system. Instead, they have a boiler, rotors that convert thermal energy to mechanical energy, and a casing region that assures the steam meets the blades under pressure. Because water is so central, there is a risk of freezing, but steam turbines can provide clean energy if renewable energy is used to heat the turbine’s cycling water.

- The modern steam turbine was created by English engineer Sir Charles Parsons in 1884, even though the principle of using steam to conduct mechanical work had been employed for a long time. The operating fluid of the steam turbine is pressurized steam from a boiler. Moving through the blades of the rotors, the superheated steam entering the turbine loses its pressure (enthalpy), and the rotors move the shaft to which they are linked.

- The thermal efficiency of a steam turbine is higher than that of a reciprocating engine, and it delivers power at a steady, consistent rate. Higher RPM states are best for steam turbine operation. The turbine is but one component of the cyclic action that generates electricity, which is best modeled by the Rankine cycle. Boilers, heat exchangers, pumps, and condensers are all part of the operation, but they’re not turbines.

The difference between a gas turbine and a steam turbine

- A gas turbine does not need supply of water. However, a steam turbine is dependent on the availability of water.

- The installation space required for a gas turbine is minimal. The installation space requirement for a steam turbine is greater.

- In comparison to a steam turbine, a gas turbine has higher efficiency.

- Flue gases are the working fluid for gas turbines. Steam gas is used as the working fluid.

- The installation and operating costs of a gas turbine are lower.

- The Brayton cycle is completed by a gas turbine. Only one step of the Rankine cycle is carried out by the steam turbine.

- In a gas turbine, changing the load is simple to control.

- Controlling a steam turbine while altering the load is tricky.

Gas turbine and Steam turbine Control system

The gas turbine Control system monitors and protects against precarious situations. GE and Woodward are some of the brands that provide turbine control systems for powerplants. The GE series includes items like DS200LDCCH1A and IS200TDBSH6A. The control software package is used with Mark VIe controllers and related systems for programming, configuring, trending, and assessing diagnostics.