Industry Spotlight: Steam Boiler Manufacturers’ Market Trends for 2024

- 1 1. Emphasis on Energy Efficiency and Sustainability

- 2 2. Adoption of Smart Technologies

- 3 3. Modular and Compact Designs

- 4 4. Enhanced Safety Features

- 5 5. Customization and Industry-Specific Solutions

- 6 6. Regulatory Compliance and Environmental Standards

- 7 7. Advancements in Materials and Manufacturing Techniques

- 8 8. Market Expansion and Globalization

- 9 Leading the Way Among Industrial Steam Boiler Manufacturers

- 10 Conclusion

As the backbone of many industrial processes, steam boilers are critical in sectors ranging from manufacturing and power generation to food processing and chemical production. In 2024, the steam boiler manufacturing industry is poised for significant changes driven by technological advancements, environmental regulations, and evolving market demands. This blog delves into the key market trends shaping the steam boiler industry 2024, offering insights into what manufacturers and businesses can expect in the coming year.

1. Emphasis on Energy Efficiency and Sustainability

High-Efficiency Boiler Systems

Energy efficiency is no longer just a buzzword; it’s a necessity. With rising fuel costs and stringent environmental regulations, industries increasingly prioritise high-efficiency steam boiler systems. These boilers are designed to maximize heat transfer and minimize energy loss, resulting in lower fuel consumption and reduced operational costs. Manufacturers focus on developing boilers that utilize advanced combustion technologies, such as staged combustion and flue gas recirculation, to enhance efficiency.

Integration of Renewable Energy Sources

Sustainability is driving innovation in the steam boiler market. Manufacturers are exploring integrating renewable energy sources, such as biomass, solar thermal, and geothermal energy, into steam boiler systems. Hybrid boilers, which combine traditional fossil fuels with renewable energy, are gaining popularity as they offer a flexible and sustainable solution for steam generation. This trend aligns with global efforts to reduce carbon emissions and dependence on non-renewable energy sources.

2. Adoption of Smart Technologies

Internet of Things (IoT) and connectivity

The Internet of Things (IoT) revolutionises the steam boiler industry by enabling real-time monitoring, data collection, and predictive maintenance. Clever boilers with IoT sensors can track key performance indicators such as temperature, pressure, and fuel usage. This data can be analyzed to optimize boiler performance, identify potential issues before they escalate, and reduce downtime. In 2024, we expect more manufacturers to incorporate IoT capabilities into their steam boilers.

Advanced Control Systems

Advanced control systems are becoming standard in modern steam boilers. These systems use sophisticated algorithms and machine learning to adjust boiler operations automatically, ensuring optimal performance and efficiency. Features such as remote monitoring, automated diagnostics, and adaptive control settings allow operators to manage boiler systems more effectively. Adopting these technologies enhances reliability, reduces operational costs, and improves overall efficiency.

3. Modular and Compact Designs

Modular Boiler Systems

Modular boiler systems offer several advantages, including flexibility, scalability, and ease of installation. These systems consist of multiple smaller units that can be combined to meet varying steam demands. Modular boilers are particularly beneficial for industries with fluctuating steam requirements, as they can be easily adjusted to match demand. The modular approach also simplifies maintenance and reduces downtime, as individual modules can be serviced without shutting down the entire system.

Space-Saving Solutions

Space constraints are a common challenge in many industrial settings. In response, manufacturers are developing compact steam boilers that deliver high performance without occupying extensive floor space. These space-saving designs are ideal for facilities with limited room for equipment, allowing them to maximize operational efficiency without compromising on steam production capabilities.

4. Enhanced Safety Features

Improved Safety Standards

Safety is a paramount concern in steam boiler operations, given the high-pressure environment and potential risks associated with boiler malfunctions. In 2024, we expect to see stricter safety standards and regulations driving the development of boilers with enhanced safety features. Manufacturers are incorporating advanced safety mechanisms such as automatic shutdown systems, pressure relief valves, and comprehensive monitoring systems to ensure safe and reliable operations.

Remote Monitoring and Diagnostics

Remote monitoring and diagnostics technology allow operators to keep track of boiler performance from anywhere, providing early warnings of potential issues and enabling proactive maintenance. This technology improves safety and extends the boiler’s lifespan by ensuring it operates within safe parameters. The adoption of remote monitoring systems is set to increase in 2024, driven by the need for improved safety and operational efficiency.

5. Customization and Industry-Specific Solutions

Tailored Boiler Solutions

Different industries have unique requirements for steam production, and one-size-fits-all solutions are often inadequate. In 2024, steam boiler manufacturers will increasingly offer customized solutions tailored to the specific needs of various industries. This trend involves designing boilers with specialized features, capacities, and configurations to meet the precise demands of food processing, pharmaceuticals, and petrochemical applications.

Industry 4.0 Integration

Integrating Industry 4.0 principles in steam boiler manufacturing will lead to more interconnected and intelligent systems. Manufacturers can create boilers that integrate with other industrial processes by leveraging advanced analytics, machine learning, and automation. This holistic approach enhances overall efficiency and productivity, enabling industries to achieve greater operational synergy.

6. Regulatory Compliance and Environmental Standards

Stricter Emission Regulations

Governments worldwide are implementing stricter emission regulations to combat climate change and reduce air pollution. Steam boiler manufacturers must comply with these regulations by developing boilers that minimize emissions of harmful pollutants such as NOx, SOx, and particulate matter. In 2024, the focus on environmentally friendly boiler designs will intensify, driving innovations in low-emission combustion technologies and exhaust gas treatment systems.

Compliance with Global Standards

Globalization has led to the harmonization of industrial standards across different regions. Steam boiler manufacturers must ensure their products comply with international standards such as those set by the American Society of Mechanical Engineers (ASME), the European Union (EU), and the International Organization for Standardization (ISO). Adhering to these standards ensures product quality and safety and facilitates market access and competitiveness.

7. Advancements in Materials and Manufacturing Techniques

Use of Advanced Materials

The development of new materials with superior properties is transforming steam boiler manufacturing. Advanced materials such as high-strength alloys, corrosion-resistant coatings, and ceramics enhance boilers’ durability, efficiency, and performance. In 2024, we can expect continued research and development in material science, leading to the creation of boilers that can withstand extreme conditions and have longer service lives.

Additive Manufacturing and 3D Printing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production of complex boiler components. ThPrinPrintingy allows precise and efficient manufacturing of parts, reducing production time and costs. In 2024, the adoption of additive manufacturing in steam boiler production will expand, enabling manufacturers to produce customized and high-performance components more easily.

8. Market Expansion and Globalization

Emerging Markets

Emerging markets in Asia, Africa, and Latin America present significant growth opportunities for steam boiler manufacturers. Rapid industrialization, urbanization, and increasing energy demands are driving the need for efficient steam generation solutions. Manufacturers will focus on expanding their presence in these regions by offering cost-effective and reliable boilers tailored to local requirements.

Strategic Partnerships and Collaborations

Steam boiler manufacturers will seek strategic partnerships and collaborations with other industry players to stay competitive in the global market. These alliances can facilitate the exchange of technology, expertise, and market access, driving innovation and growth. In 2024, more manufacturers will form joint ventures, research collaborations, and distribution agreements to strengthen their market position.

Leading the Way Among Industrial Steam Boiler Manufacturers

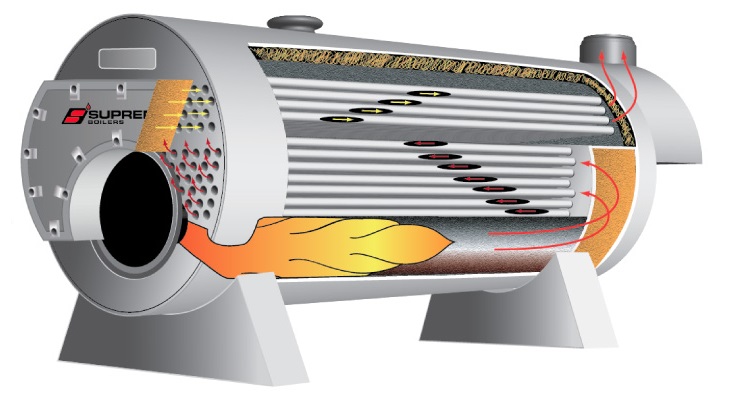

Supreme Boilers stands out among industrial steam boiler manufacturers when it comes to reliability, efficiency, and innovation in steam boiler technology. With a commitment to delivering high-performance solutions, Supreme Boilers offers a range of advanced steam boiler systems designed to meet the diverse needs of various industries. Their products incorporate the latest energy-efficient technology and robust safety features, ensuring optimal performance and compliance with stringent environmental standards. Discover how Supreme Boilers can enhance your operations by visiting Supreme Boilers.

Conclusion

The steam boiler manufacturing industry is undergoing significant transformations in 2024, driven by technological advancements, sustainability initiatives, and evolving market demands. Energy efficiency and sustainability will be at the forefront, with high-efficiency boilers and renewable energy integration becoming increasingly important. Adopting intelligent technologies, modular designs, enhanced safety features, and industry-specific solutions will further improve the performance and adaptability of steam boilers.

Manufacturers must navigate stricter regulatory compliance, leverage advanced materials and manufacturing techniques, and explore new markets and strategic partnerships to stay competitive. As the industry continues to innovate and evolve, businesses can look forward to more efficient, reliable, and sustainable steam generation solutions that meet their diverse needs.

By staying informed about these trends and choosing the proper steam boiler manufacturer, businesses can ensure they are well-equipped to tackle the challenges and opportunities of 2024 and beyond. Embrace the future of steam boiler technology and prioritise efficiency in the coming year.